"responsibility,sustainibility,sensibility"

ISO 13485:2016 -ISO 9001:2015. - ISO 10002:2018 - ISO 14001:2015 - ISO 45001:2018 - NATO CAGE:DN821

"responsibility,sustainibility,sensibility"

ISO 13485:2016 -ISO 9001:2015. - ISO 10002:2018 - ISO 14001:2015 - ISO 45001:2018 - NATO CAGE:DN821

Customer satisfaction is the top priority AT Technologies GmbH (ATG). We therefore customize to meet your needs and standards. ATG specializes in the surface treatment of for steel structural elements. The main objective is to realize your ideas and to guarantee the maintenance. Depending on your needs, ATG will develop a solution for the coating. Our customers have always remained loyal to us since with experienced and reliable staff we can find solutions to any problem.

Bridges are an important part of any country's transportation infrastructure. They help us with daily activities such as walking, driving, and even taking trains across roads, rivers and valleys. The goal of ATG is to significantly extend the life of the structure of a bridge while also contributing to its visual appeal.

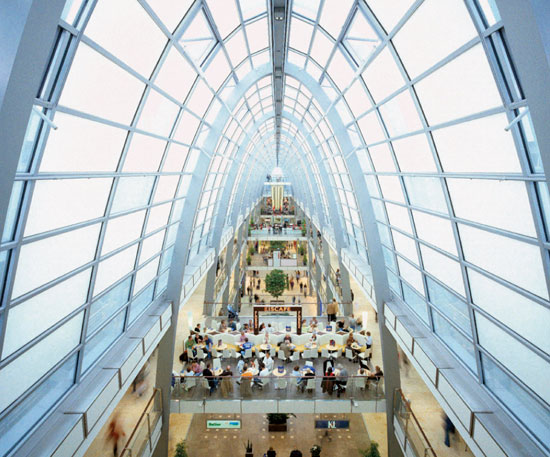

To satisfy the investors’ demands for larger and tall constructions, architects incorporate more steel into their designs. Depending on the planned lifespan of the building and the surrounding atmospheric conditions, various corrosion protection systems are required. ATG provides the right solution for each project. This may be a cost-effective single coating system, or it may be a multilayer coating based on two-component materials.

The product range provided by our partner manufacturer lets our company include coatings that comply with current technical regulations, as well as various variants of "tailored corrosion protection" for special individual cases.

And sometimes, a special selection a coating system for a new investment can be trouble in financial resources. We are here to assist you with the right advice and service.

Special technical requirement specifications call for suitable coatings. The challenges are resistance to any chemicals and resistance for high temperatures (such as chimneys and flues).

In order to be able to construct structures throughout the year and regardless of the weather conditions, the coating work is moved and carried out in the factory wherever its possible. Coating a fabricated steel construction element while they are still in the hall, a material that hardens quickly is needed. These issues need to be dealt as soon as possible and transportation damage should be avoided or/and minimized.

Together with G& W we offer the duplex system. It is a combination of hot galvanization with a suitable anti-corrosion coating. In addition to the possibility of color design, the coating also offers many technical advantages.

Very good corrosion protection properties with long protection periods are possible with both coating systems and a hot-dip galvanizing. A combination of both sums up a protection period of 25 to 50 years is possible.

Hydro coating systems are particularly well suited for reducing volatile organic compound emissions (VOCs). ATG not only meets many different individual customer requirements but has also influenced the current state of technology.

ATG offers through G&W which is one of the first manufacturers to develop hydro coating materials as early as in 1970. One of the first major customers in the '70s was IBM, who used the offered hydro products for their computer housing coating.

Since the commercial launch of hydro coating materials, approx. 7,000 t of organic solvents have been saved by G&W products.This is possible with various high solids coating materials. In accordance with customer requirements (substrate, substrate pretreatment, corrosion protection and appearance) coating materials with a high solid content (= high-solids) are generally based on epoxy, epoxy combination, polyurethane, alkyd/acrylic and urethane-modified alkyd resins.

Advantages of high-solids coating materials:

To avoid harmful chemicals, electrochemical and physical attacks on steel components, corrosion must be prevented. Corrosion protection is therefore more important than ever and affects all economic sectors. These measures are carried out by our staff using environmentally safe painting and coating materials.

Our services: Surface preparation and subsequent coating work with the necessary planning.

High quality of our coatings involves many preconditions. There must be an evaluation of the current condition, the precise planning of the materials that are to be coated and an understanding of the professional process on surfaces.

Depending on the initial condition of the surface, different procedures can be applied, which tells us which measures need to be taken. Whether dirt, old coatings, and corrosion – they need to be removed by either compressed air blasting or high-pressure cleaning with solid abrasives.

The following ISO 9001:2015, ISO 14001:2015, ISO 10002:2018 and ISO 45001:2018 are a recognized standard that provides good assistance in selecting the appropriate coating system for steel components and its safety.

Touch ups in the sectors mentioned is also the scope of ATG. Over the years, the protection dissolves and we are there to prevent this. For this purpose, regular touch ups are made to be able to protect the environment and the life around it. ATG offers special permanent conductive coating systems and services for the various legal standards and areas of application.